Brazed or welded

There are many ways to make a metal bicycle frame: lugs, fillet brazing, TIG, gas, or MIG welding, and probably others. Some are not very suitable for making high-quality frames (MIG/gas welding), but the others, while well suited to making bikes, have their positives and negatives.

I primarily use fillet brazing to make bicycle frames, and I am biased. Keep that in mind if you read further. In the following, I will make the assumption that the person doing the welding/brazing knows what they are doing, and I will give my opinion on the various techniques that can be used to make a good bicycle frame.

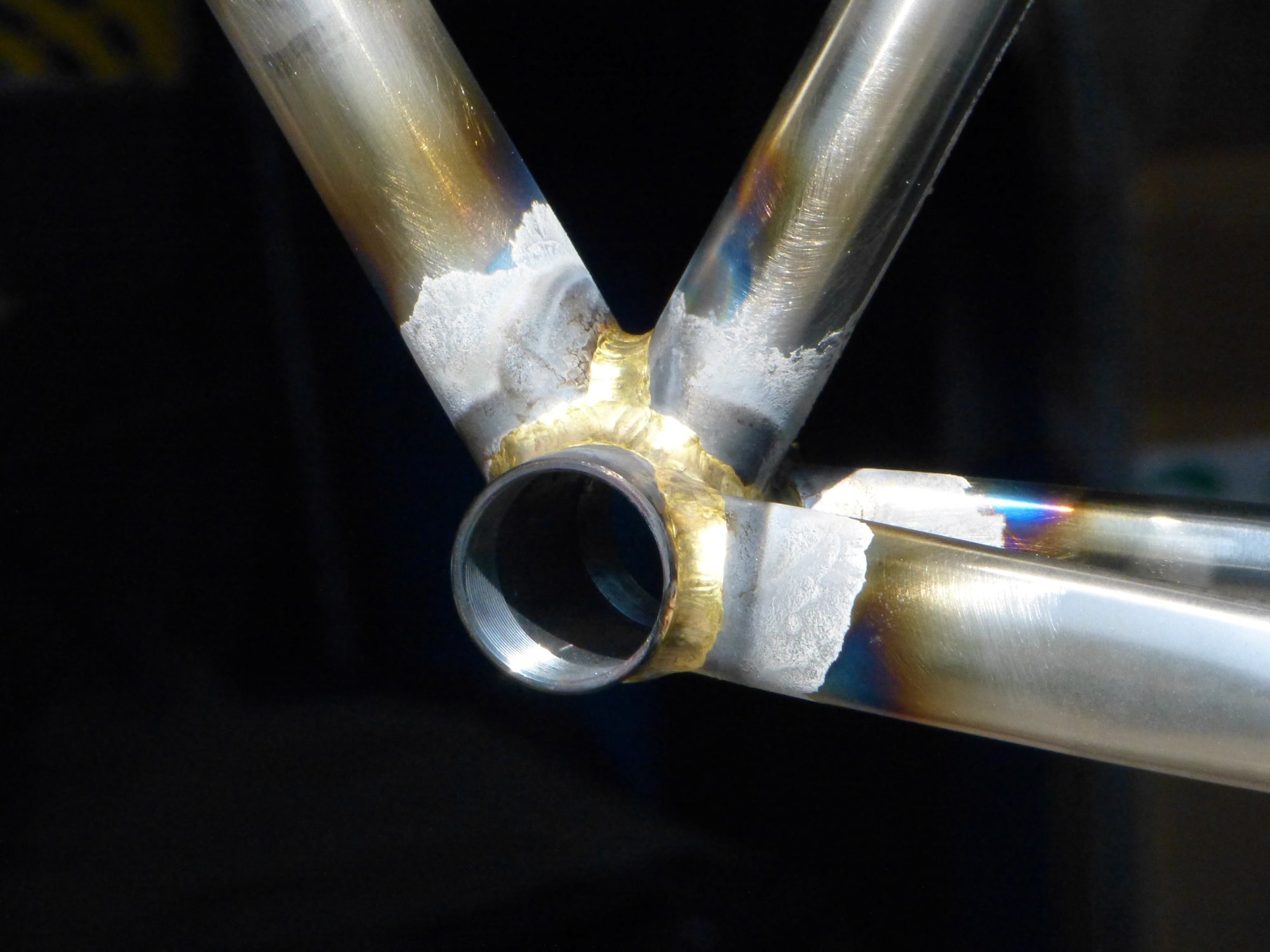

First, let’s get the basics covered: Welding and brazing are both ways of fixing two pieces of metal together. The difference between the two is that in welding, the pieces of metal you are joining together get melted, whereas in brazing, they don’t. There are many welding techniques, but all of them melt the parent material. Brazing can be split in two very broad categories: fillet and capillary brazing. If you make a lugged bike frame, you will use capillary brazing: You fill the cavity between the lug and the tube with a filler material via capillary action and heat gradients. Fillet brazing, instead, uses the filler material to construct a structurally sound bead of material that goes right from the foot of the joint outwards into a smooth “fillet”, which is characteristic of the fillet-brazed frame.

From the distinction between welding and brazing, we immediately see that welding involves higher temperatures than brazing. At high temperatures, the metal will change its mechanical properties. So, in theory, working at lower temperatures (i.e., brazing) should be advantageous. However, the heat-affected zone is generally larger in brazing, so overall the two processes are comparable.

Lugs are super cool. They can be carved into amazingly intricate pieces, and they make for a classic look1. The style of the lug can be changed to be simple and clean or super ornate. I like lugs. The main disadvantage of lugs is that the geometry (angles and tube diameters) is dictated by the lugs that are available. Given that lugs are not so widely used any longer, the choice is not great. Trying to make a modern bike with lugs is not impossible, but you do add an extra challenge to the process. And making a cargo bike with lugs and curved tubes would be impossible (though it would be unbelievably cool). I don’t use many lugs in my work.

TIG welding is brilliant. It leaves a small weld bead, and a skilled TIG welder can make a strong, beautiful joint. I love the look of a good TIG weld. TIG welding, for me, has a bit of an industrial feel, however. TIG welding is excellent where you need a super-efficient process. And it is widely used in such a setting. As a result, TIG is often associated with industrially produced products. I am making hand-made products one at a time. For me, there would be a dissonance between the product and the process if I were to TIG weld my frames. If I believed it made for a superior product, I would use this process, but it doesn’t.

Fillet brazing is the process that I use, and if I could, I would do nothing but fillet brazing all day long. Different materials can be joined using different fillers. Low(ish) temperatures are used throughout the process, which can minimize heat distortion and mechanical degradation of the tubes; it is a process that maintains a high degree of design flexibility, and it makes for a beautiful object. There is something magical about using a torch to make the filler flow just as you want, creating smooth curves and uniform fillets. There is something different to this process; there is a magic here. I don’t believe that fillet brazing is the only way to make a beautiful bike. But it is the process I use, and I think it is wonderful.

Notes

1 My understanding is that lugs were developed when bicycle frames were made in forges; the constructor got the metal red hot and then got the metal to flow (via capillary action/heat gradients) into the joint. Penetration wasn’t always great, but it worked.

If you have any questions/comments about this post, please contact me here.